We are proud to announce that HTS has been awarded Innovate UK funding to test concrete-encased steel from the 1950s for reuse, with support from UKRI Interdisciplinary Centre for Circular Metals.

This is our first collaboration with Innovate UK, the UK’s leading innovation agency driving productivity and economic growth by supporting businesses to develop and realise the potential of new ideas.

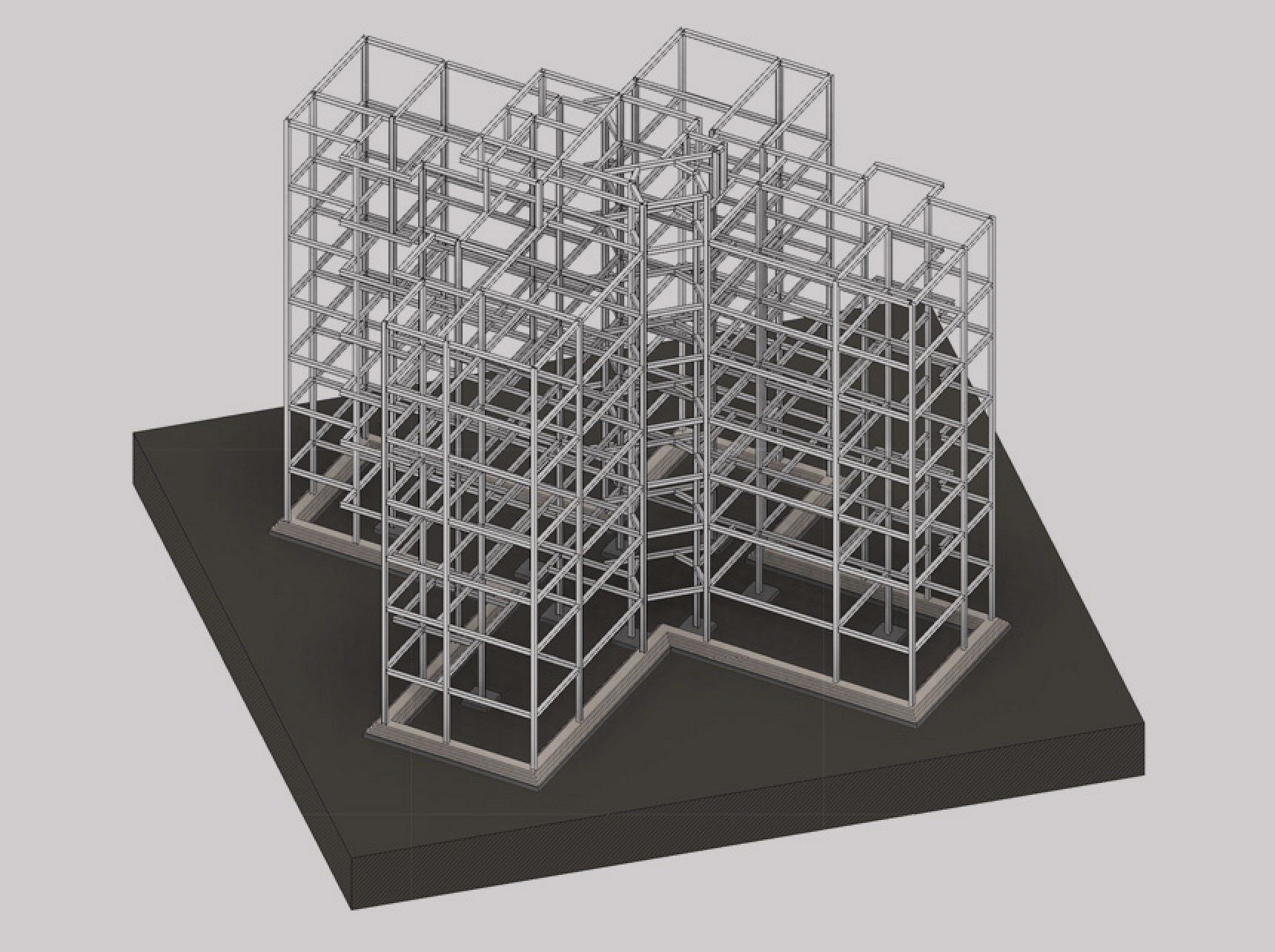

Our in-house innovation and research team HTS+ will use the grant to test and assess the concrete-encased steel beams and columns within one of four buildings in Belgravia. The building sits within a larger 1950s development being transformed by Grosvenor.

Advancing the Reuse of Steel

Reusing steel makes for a far less energy-intensive process than melting and recycling steel and has a substantial carbon footprint reduction of 8x less than its traditional steel counterpart. Reusing steel also avoids repeated imports and exports – in the UK we export 75% of our scrap steel as we don’t have the capacity to recycle it. Currently, we are only permitted to reuse steel made from 1970, despite modern steelmaking spanning back to 1855.

Our pioneering project seeks to expand the range of steel for reuse in a way that is both effective and environmentally sustainable.

Next Steps

Initial investigations have already been undertaken to estimate steel grade and condition of the building, with collaboration with the demolition contractor underway, to test various ways of removing the concrete encasement without causing too much damage to the steels. The building is due to be dismantled at the start of Summer 2022 and steel sections will be made available shortly after to test.

Our exploration will allow us to see the benefits of reusing steel within existing buildings, posing an alternative and more effective process to consider when sourcing reusable steel for future projects.