After water, concrete is the most widely used material on earth. Its use dates back millennia and can be traced to the ancient Egyptians. In some ways concrete is the perfect building material. It is fluid when brought to site, making it malleable for pouring and moulding, it’s quick drying, and has 10 times the compressive strength of brickwork while being a similar weight.

However, these material benefits come with a high carbon cost. Owing to the energy intensive combustion process involved in the production of cement, concrete accounts for around 8 per cent of global CO2 emissions.

In short, concrete has a carbon problem.

The Solutions

There now exist a number of different practices to make concrete more efficient. The most common approach is the simplest: use less. Intelligent engineering solutions such as post-tensioning concrete and ultra-high strength concrete reduces the volume of material required but come with their own disadvantages and are limited in their efficacy.

Post-tensioning a slab may save 20% of the concrete volume but to reach net-zero targets, we need to do better. Ultra-high strength concrete can reduce the thickness of members by 40% but given that it requires a much higher portion of cement in the mix, the carbon savings are limited. We believe the key to making concrete a more sustainable building material is cement replacement: taking cement out of the mix and replacing it with a similar material.

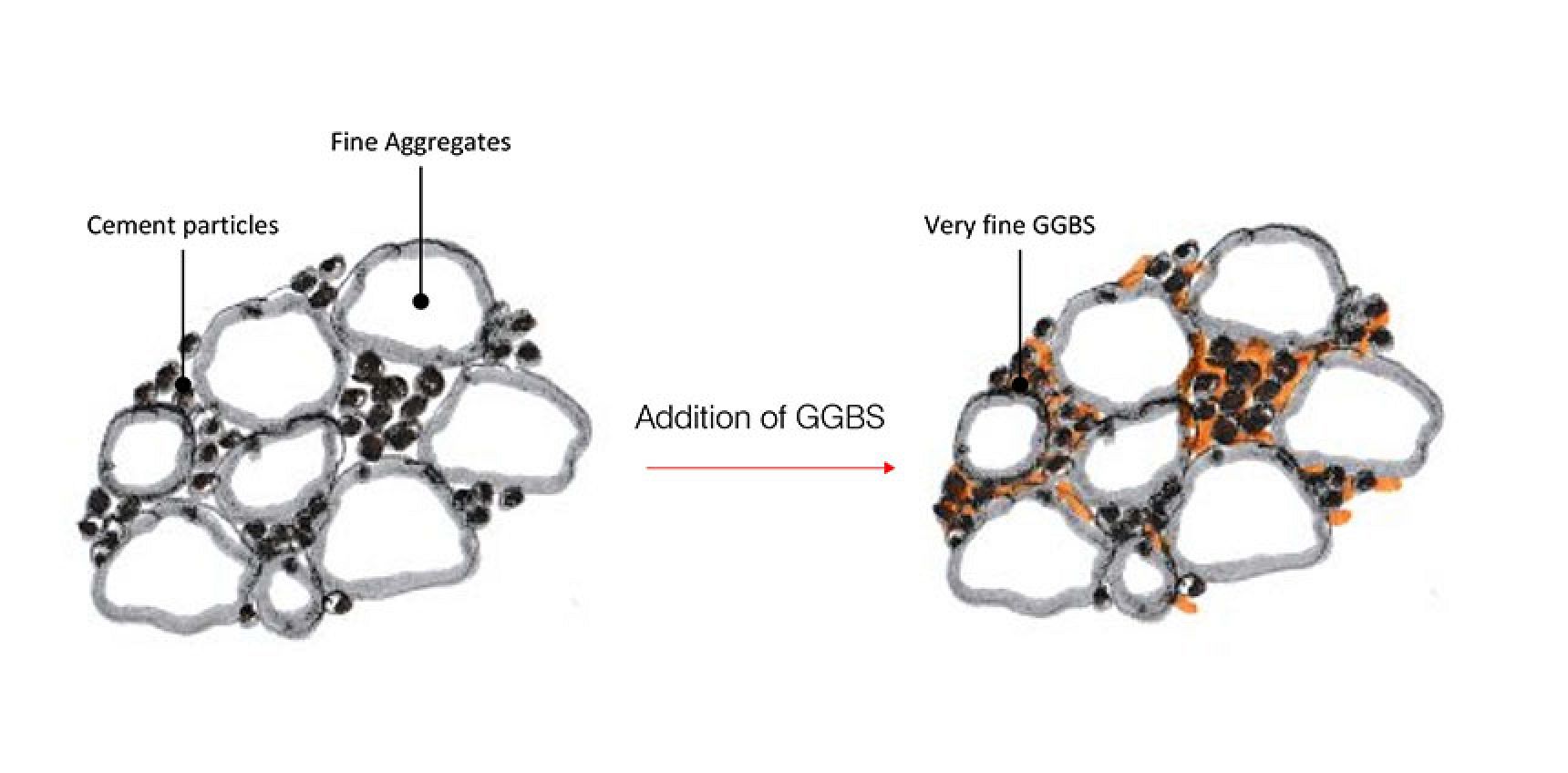

The chemical reactions that occur during the hydration of concrete are complicated, but the basic principles are simple: calcium and silica present in the cement react with water and harden around the aggregates. The cement acts as a binder to the aggregate so to replace the cement binder we just need a material with high levels of calcium and silica.

Enter, ground granulated blastfurnace[SW1] slag (GGBS), a waste product of iron production. For years this waste product – coined ‘slag - has ended up in landfill as it is an unwanted by-product. Instead of sending it to landfill, the slag is instead dropped in water and ground to a fine powder to form a material which is chemically very similar to cement and can be used as a replacement binder.

GGBS – The common questions

How much carbon is saved?

The production of GGBS contains 1/15th the amount of carbon as ordinary cement.

Can we replace all the cement?

To start the hardening process, the pH needs to be higher than 7 so we need at least 5% cement as a total binder content. A workable structural mix ideally removes 60-75% of cement and replaces it with GGBS. Traditionally most concrete contained 100% cement as a binder content.

Is it the same as cement?

Chemically, it is very similar. However, it’s a lot finer than cement, meaning small pores in between the remaining cement particles are filled making the concrete harder and giving the concrete many beneficial properties.

[SW1]Is this not blastfurnace?

There now exist a number of different practices to make concrete more efficient. The most common approach is the simplest: use less. Intelligent engineering solutions such as post-tensioning concrete and ultra-high strength concrete reduces the volume of material required but come with their own disadvantages and are limited in their efficacy.

Post-tensioning a slab may save 20% of the concrete volume but to reach net-zero targets, we need to do better. Ultra-high strength concrete can reduce the thickness of members by 40% but given that it requires a much higher portion of cement in the mix, the carbon savings are limited. We believe the key to making concrete a more sustainable building material is cement replacement: taking cement out of the mix and replacing it with a similar material.

The chemical reactions that occur during the hydration of concrete are complicated, but the basic principles are simple: calcium and silica present in the cement react with water and harden around the aggregates. The cement acts as a binder to the aggregate so to replace the cement binder we just need a material with high levels of calcium and silica.

Enter, ground granulated blastfurnace slag (GGBS), a waste product of iron production. For years this waste product – coined ‘slag - has ended up in landfill as it is an unwanted by-product. Instead of sending it to landfill, the slag is instead dropped in water and ground to a fine powder to form a material which is chemically very similar to cement and can be used as a replacement binder.

To help lower the embodied carbon in our structures, we regularly specify high percentage GGBS content in concrete. Most recently this includes The University of Winchester West Downs centre and 100 Union Street where the exposed light concrete finish was produced from high GGBS content as well as The Featherstone Building where all columns have been specified with 50% GGBS content, floor slabs with 30% and core walls with 20%.

The production of GGBS contains 1/15th the amount of carbon as ordinary cement.

To start the hardening process, the pH needs to be higher than 7 so we need at least 5% cement as a total binder content. A workable structural mix ideally removes 60-75% of cement and replaces it with GGBS. Traditionally most concrete contained 100% cement as a binder content.

Chemically, it is very similar. However, it’s a lot finer than cement, meaning small pores in between the remaining cement particles are filled making the concrete harder and giving the concrete many beneficial properties.

There now exist a number of different practices to make concrete more efficient. The most common approach is the simplest: use less. Intelligent engineering solutions such as post-tensioning concrete and ultra-high strength concrete reduces the volume of material required but come with their own disadvantages and are limited in their efficacy.

Post-tensioning a slab may save 20% of the concrete volume but to reach net-zero targets, we need to do better. Ultra-high strength concrete can reduce the thickness of members by 40% but given that it requires a much higher portion of cement in the mix, the carbon savings are limited. We believe the key to making concrete a more sustainable building material is cement replacement: taking cement out of the mix and replacing it with a similar material.

The chemical reactions that occur during the hydration of concrete are complicated, but the basic principles are simple: calcium and silica present in the cement react with water and harden around the aggregates. The cement acts as a binder to the aggregate so to replace the cement binder we just need a material with high levels of calcium and silica.

Enter, ground granulated blastfurnace[SW1] slag (GGBS), a waste product of iron production. For years this waste product – coined ‘slag - has ended up in landfill as it is an unwanted by-product. Instead of sending it to landfill, the slag is instead dropped in water and ground to a fine powder to form a material which is chemically very similar to cement and can be used as a replacement binder.

To help lower the embodied carbon in our structures, we regularly specify high percentage GGBS content in concrete. Most recently this includes The University of Winchester West Downs centre and 100 Union Street where the exposed light concrete finish was produced from high GGBS content as well as The Featherstone Building where all columns have been specified with 50% GGBS content, floor slabs with 30% and core walls with 20%.

[SW1]Is this not blastfurnace?

No! GGBS is not a new invention, we have been using it since the 1860s in Europe and the 1920s in the UK.

We are now beginning to use it widely across the UK: HS2 is using 30% GGBS as standard in its mixes. To help with increasing demand, we are now importing more from Europe and around the world. This is a signpost to a future problem: GGBS is itself a finite resource and global production already does not meet demand for cement. This is a trend that will get worse in the future and is explored in the second article in this series.

Concrete mixed with high rates of GGBS cure slower than ordinary concrete, especially at cold temperatures. With a typical 70% GGBS mix with 30% cement, after 3 days the cement is 45% weaker than a 100% cement mix and after 7 days is 20% weaker. After 1 month the strengths are the same.

Key considerations

Early age gain is an important factor to consider, especially for tall and multistorey buildings.

Ordinarily, a contractor would look to cast a floor per week. Once a floor is cast, props are installed for the next floor and reinforcement is installed. When the slab above is poured, the slab below takes all the load. This is most likely the highest load the slab will ever see. The slab needs to be strong enough to take these loads at the point at which the next floor is introduced or the contractor will have to delay.

Concrete with high GGBS content cures slower and it is often difficult to prove that the concrete is strong enough to take the loads above.

At cold temperatures, this effect is worsened and high GGBS content concrete cures much slower but still reaches the same strength as concrete made from 100% cement after 28 days.

Mitigating the effects of high GGBS concrete

Low carbon buildings come at a premium, this may be in the form of a longer programme or higher cost. Our job as engineers is to minimise this premium to ensure we can continue to build sustainably.

Concrete with high GGBS content may extend the programme by up to several days per floor, depending on temperature. But we have several tools to minimise these programme implications.

Traditionally, concrete cubes are taken when concrete is poured on site. These cubes are often kept in the site office or in a shed and crushed at various times to prove the concrete strength. Concrete curing is an exothermic reaction – heat is given out as it hardens, large areas of slab will likely see a 15°C increase in temperature and the cubes sat in a nearby shed aren’t seeing this heat.

Concrete with high GGBS content cures slower and it is often difficult to prove that the concrete is strong enough to take the loads above.

At cold temperatures, this effect is worsened and high GGBS content concrete cures much slower but still reaches the same strength as concrete made from 100% cement after 28 days.

Mitigating the effects of high GGBS concrete

Low carbon buildings come at a premium, this may be in the form of a longer programme or higher cost. Our job as engineers is to minimise this premium to ensure we can continue to build sustainably.

Concrete with high GGBS content may extend the programme by up to several days per floor, depending on temperature. But we have several tools to minimise these programme implications. [LH1]

1. Temperature monitoring

Traditionally, concrete cubes are taken when concrete is poured on site. These cubes are often kept in the site office or in a shed and crushed at various times to prove the concrete strength. Concrete curing is an exothermic reaction – heat is given out as it hardens, large areas of slab will likely see a 15°C increase in temperature and the cubes sat in a nearby shed aren’t seeing this heat.

[LH1]Could we name any?